Micro turbines pioneer eng. Kurt Schreckling build three prototypes FD-1,FD-2, FD3/64 considering his practice third engine work "as expected". He also design KJ-66 which is common layout for majority of model turbines.

From my experience :

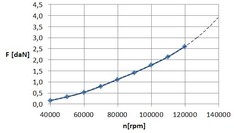

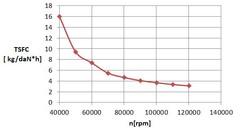

Engine: no.1 mSO-1, no.2 GT60, no.3 GT60A1

https://www.youtube.com/watch?v=r7HeeL3825I

After first prototype - I know that without experience "scientific effort" are more or less "wishfull thinking",

second prototype - I know that design decision was better but needs to be redesigned once again,

third prototype - I know that's design is good and needs tweaking to be reliable as commercial products.

Summarizing - four compressor designs, four combustor designs, three rotor/internal and two turbine designs, 1+ jetpipe designs, excluding parts that needs to be remanufactured due different reasons.

The best of this project to me is to feel comfortable with "engineering experience".

By itself, competence is meaningless without character and good judgment.” ― Harold G. Moore